The History of Coin Minting

The Origins of Coin Minting: From Ingots to Art

Imagine a time when coins weren’t just convenient currency—they were revolutionary tools that fueled ancient empires. The story of coin minting begins over 2,500 years ago in the ancient kingdoms of Lydia (modern-day Turkey). These first coins, made of a naturally occurring gold-silver alloy called electrum, were more than mere money; they were symbols of power, prestige, and trust.

Early minting was no polished process. Picture craftsmen hammering molten metal into rough discs, imprinting them with royal seals using hand-carved dies. Each coin captured the human touch—an imperfect masterpiece. Over time, this evolved into the remarkable art form we now admire.

Ancient Milestones That Shaped Minting

The journey of minting is studded with fascinating milestones:

- Greek inventiveness: Greece elevated minting to high art, etching gods, heroes, and myths onto coins that could tell a tale in a single glance.

- Roman efficiency: Romans industrialized the process, producing standardized coins that powered an empire stretching across continents.

- The Middle Ages: Feudal lords minted coins to assert their rule, often embedding secret symbols to thwart forgers.

From humble beginnings to awe-inspiring craftsmanship, every coin carries the echo of centuries past, a tiny artifact whispering stories through the ages.

Modern Coin Minting Techniques and Innovations

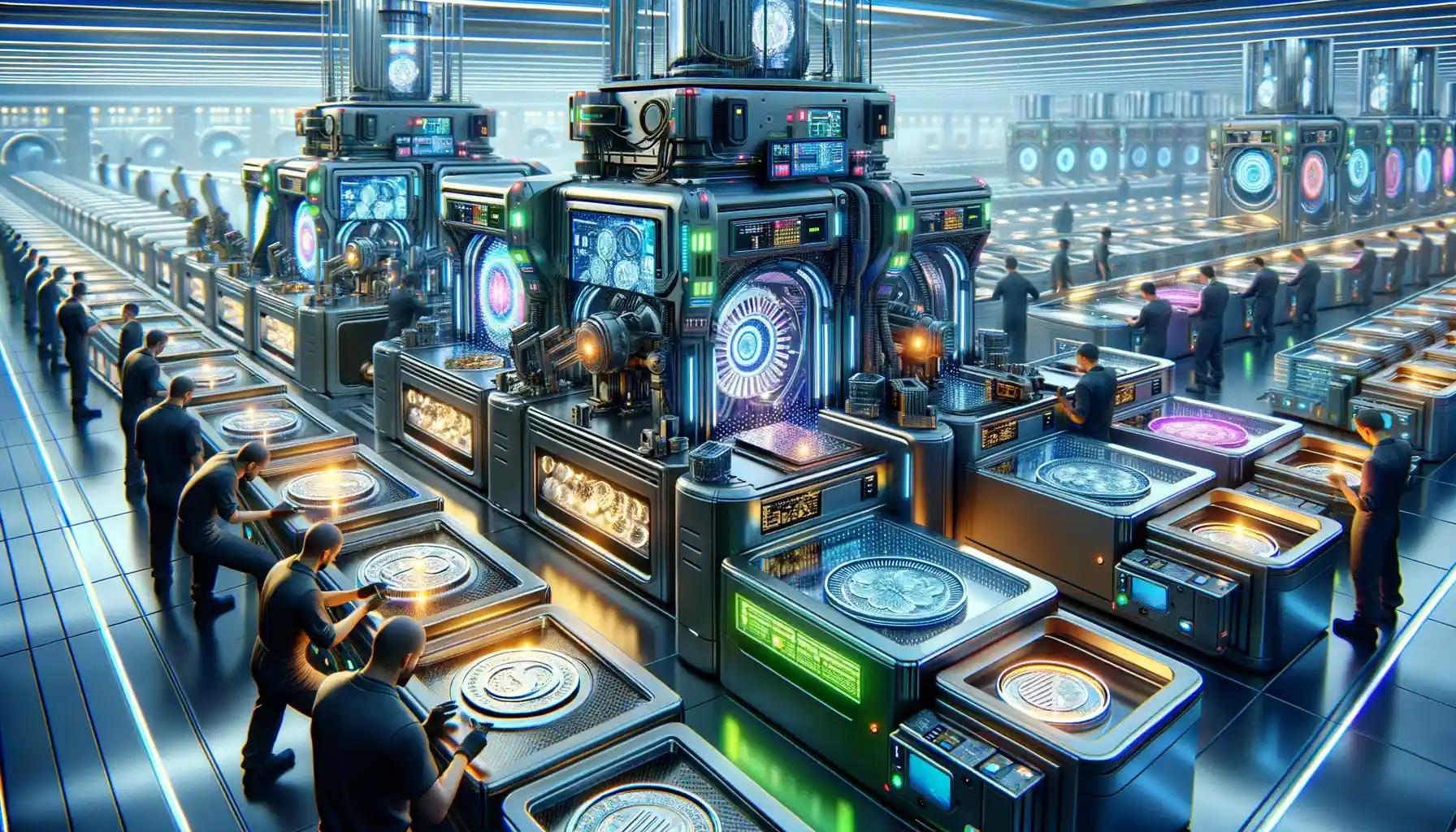

Cutting-Edge Technologies at the Heart of Modern Coin Creation

Imagine a gleaming lab where tradition meets cutting-edge tech. Today’s coin minting is no longer just about brute force stamping metal; it’s an intricate dance involving lasers, scanners, and astonishing precision. Let’s talk about the wonders behind it.

First, consider the role of computer-aided design (CAD). Artists now sketch their ideas digitally, turning creative visions into mock-ups that dazzle even before they’re minted. A far cry from hand-engraved dies of yore, right? These digital designs allow for near-impossible details—think micro-text or holographic-like effects that shimmer as you turn the coin in your hand.

Then there’s laser engraving, a game-changer in the way dies are etched. This isn’t your grandfather’s engraving tool! Lasers carve designs with microscopic precision, capturing textures as fine as a fingerprint. And let’s not ignore robotics—automated presses churn out coins not only faster but with unrivaled consistency.

- Electroplating to create stunning color finishes

- Edge lettering that hides secret messages

- Multi-metal layers for visual pop

The result? Coins that feel less like currency and more like miniature masterpieces.

The Role of Coin Design in Minting

The Emotion Behind Coin Design

What’s the first thing you notice when you hold a coin in your hand? The weight, maybe. The shine. But let’s be real—it’s the design that grabs your attention and tells a story. Coin design isn’t just decoration; it’s art infused with culture, history, and identity. Every curve, symbol, and inscription is deliberate, carrying meaning far beyond the metal it’s struck on.

Think of the intricate swirls on a commemorative coin or the confident face of a monarch emblazoned across currency. These aren’t random choices—they’re crafted to evoke emotion. A good coin design doesn’t simply sit in your pocket; it whispers—no, shouts—who we are and what we value. It’s like a miniature billboard for an entire nation.

- The bold eagle etched into American coins stands as a symbol of power and resilience.

- The delicate cherry blossoms on Japanese yen reflect natural beauty and peace.

- Even obscure designs, like the Viking ships on old Norwegian coins, stir curiosity and pride in heritage.

The Dance Between Artistry and Function

Here’s the kicker: designing a coin isn’t just about making it beautiful. Oh no—it has to be practical too. Coins need to stack. They must resist wear and tear, all while staying instantly recognizable in a jangling purse or under dim light. Artists and engravers work closely with engineers to bring visions to life—often sacrificing details they love for the sake of functionality.

Imagine this: a designer creates an intricate web of stars for a new coin design. Stunning on paper but impossible to mint without breakage. Back to the drawing board. It’s not a job for the faint-hearted! That’s the constant push-pull of coin design—a tightrope walk between aesthetics and practicality, where every millimeter matters.

And when the balance is nailed? It’s magic. Think of the perfect symmetry of the Greek drachma or the iconic Maple Leaf of Canadian coins. These designs don’t just meet technical standards—they inspire awe. And isn’t that worth more than gold?

Challenges in Coin Production Over Time

The Hidden Struggles Behind the Shine

Coins may look effortless in their gleaming perfection, but every minting era has wrestled with its own set of headaches. Think about the ancient days—craftsmen striking coins by hand, one strike at a time. Sounds romantic, right? But imagine the blisters from wielding heavy hammers all day! Not to mention how uneven those early coins could be.

Fast forward to industrial times, and you’ve got machines churning out coins by the second. Problem solved? Not so fast! Machines introduced their own challenges—breakdowns were frequent, and precision was tough to maintain without advanced technology. A slight miscalculation could warp entire batches, costing a fortune.

Modern Challenges That Still Keep Us On Edge

Even today, with all our tech wizardry, coin production isn’t immune to dilemmas:

- Material scarcity: Metals like copper and nickel fluctuate in supply and cost, forcing mints to adapt quickly.

- Anti-counterfeiting: Designing coins that are tough to fake while keeping costs reasonable? It’s like threading a needle in the dark.

- Wear resistance: Ever held an old coin worn so smooth you couldn’t read it? Balancing durability with affordability remains an ongoing puzzle.

From ancient hammers to cutting-edge lasers, every generation faces its coin-shaped conundrums. And yet, we keep solving them—because, deep down, every coin is more than metal. It’s history in your pocket.

Future Trends in Coin Minting

Revolutionary Materials and Green Minting

Imagine coins crafted not just from the usual suspects like silver or nickel, but from groundbreaking materials that are lighter, stronger, and more sustainable. The future of coin minting is leaning heavily toward eco-friendly practices. Picture this: mints adopting recycled metals or even experimenting with biodegradable compounds—coins that could one day return to the earth as gracefully as they emerged from it.

And here’s the kicker: energy-efficient minting processes are becoming a reality. Mints worldwide are exploring renewable energy sources, such as solar-powered presses and geothermal-driven machinery. This isn’t just about cutting costs; it’s about transforming an age-old craft into something harmonious with our planet.

- Digital twin technology: Imagine every coin having a virtual counterpart, tracked through blockchain for traceability and authenticity.

- Precision-level nanotechnology: Creating intricate details on coins so sharp it feels like holding a miniature artwork in your palm.

Personalized Coins Powered by Technology

Ever dreamed of your portrait on a coin? Welcome to the era of personalization! With advancements in AI-driven engraving tools, custom coin design is set to flourish. Whether it’s celebrating a life milestone or commemorating cultural heritage, the coins of tomorrow will tell deeply personal stories.

And let’s not forget the integration of smart tech. Coins embedded with invisible QR codes or NFC chips could unlock digital content—historical narratives, audio guides, or even augmented reality experiences of the minted designs. The humble coin is evolving into a tiny vessel for endless possibilities.